D2 - 1.2379

D3 - 1.2080 or Richard Carr 23s

D2 is a semi-stainless steel with a content of 14% chrome. I have used this myself for all my knife making career and in fact D2 is one of the most produced knife steels for industry. I have done a lot of heat treatment on this steel to get an optimum heat treatment for edge retention. I harden the full blade so it will not have a differential hardness. This is because in the past I have put a differential hardness on knives but the softer steel does marr and rust much more than the hardened D2 edge area.

It is quite a difficult steel to learn to forge with. I would not recommend beginners to start forging blades with D2 because it is difficult.

D3 has a higher carbon content with just about the same characteristics as D2.

Unfortunately D2 and D3 are much maligned blade steels by certain forum groups on the internet. I can understand this because if D2 is badly heattreated it is really crap. But if the heat treatment is done correctly it is as good a knife steel as anyone can wish for.

-

D2 - D3

-

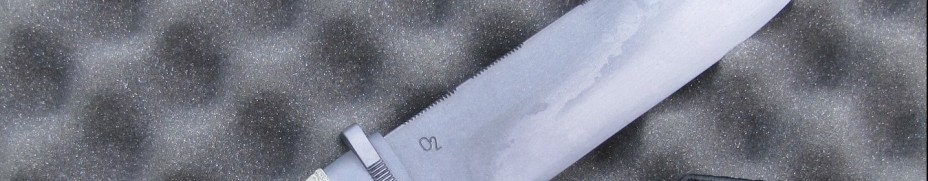

O2

O2 - 1:2842

O2 is a hyperutectic tool steel. It has a carbon content of over 1%. I have used this forever. I only source it from Lohmanns steel or Boker in Austria. This makes a very good blade with very good cutting characteristics and toughness. I can water quench it to get a differential hardness, as seen in the pictures as the lighter grey area near the cutting edge. -

BB

BB (Ball Bearing) 1.3505

BB is another carbon steel I use for blades. It is proven to be a very good blade steel with all the right characteristics for user blades. I can water quench it to create a differential hardness as can be seen in the pictures. -

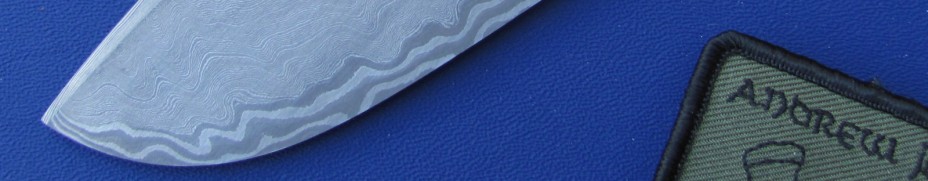

Nickel Random Damast

Nickel Random Damast

As the name implies I am using a nickel based carbon steel in the category of 15N20. The other steel is 1.2842. This makes a good a user blade steel which is slightly more silky then the carbon based counterpart of Templar Steel. I can give RD (Random Damast) a differential hardness as you can see on some of the pictures or a fully hardened blade as the client wishes. The first picture shows a differential hardness Random Damast blade, the last picture is a fully hardened Random Damast blade. -

Sandwich damast

Sandwich Damast/ Sandwich Patternweld (formerly Elite Gold)

As the name describes this is a pattern welded blade steel. The two outer slabs are 15N20 and 1.2842 to a 200 layer count. The center, as you can see, shows through on the knives (on the 5th picture this is clearest). The core material is a mixture of 3 steels: 15N20, 1.2842 and a cobalt steel to a layer count of 30-40 layers.

This steel is proven to be an outstanding blade steel. It holds an aggresive cutting edge. It takes a little longer to make sandwich damast so the price is different from from the random pattern weld nickle and carbon damasts I make.

If you want a true performance steel for your knife you should certainly think about this sandwich damast as an option. -

Counterfold

Counterfold

Counterfold is a mixture of white paper steel and 1.2842. The layer count is taken to around 150 layers and then the billet is set on its side and the side grain is hammered down into a long plate. This is then folded and welded three times, then turned again and squared into a long square bar, 5 bars thick and forge welded. Then the bar is cut in the middle and folded on itself and then forge welded creating 10 bars.

This makes a very good cutting edge for a user knife.